Business Process

Oracle International relies on the 8-step manufacturing business process as a cornerstone for crafting premium brass components. Let’s delve into each step of this meticulous process, This 8-step manufacturing process at Oracle International ensures the production of exceptional brass products. Each step plays a vital role in guaranteeing the quality and reliability of the final result. With a strong commitment to quality and customer satisfaction, Oracle International delivers brass components of the highest standard.

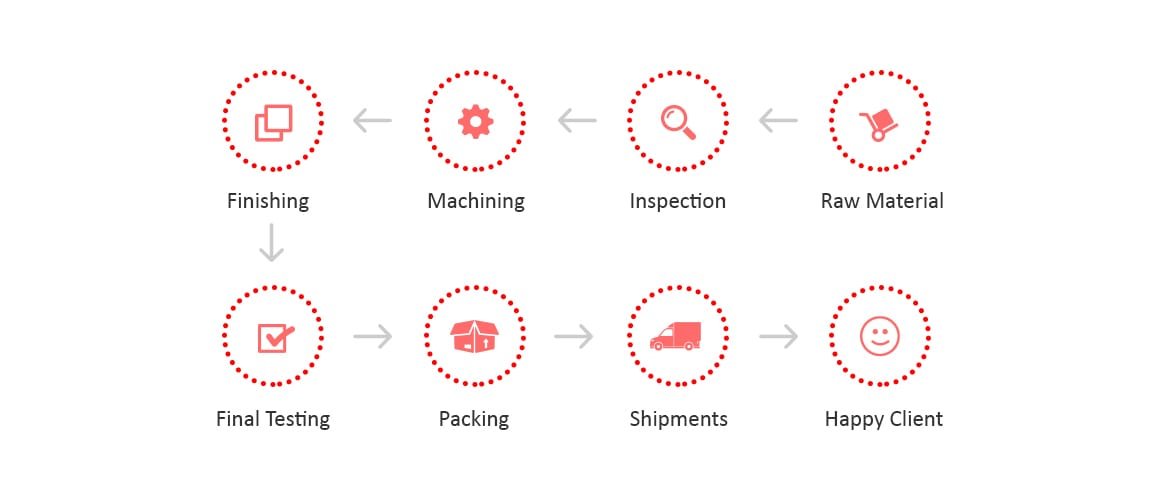

8-Step Manufacturing Business Process We Follow

Quality Raw Material:

The foundation of manufacturing brass components lies in sourcing high-quality raw materials through a meticulous business process. With a keen eye for excellence, reputable suppliers provide brass alloys that meet stringent specifications for composition, purity, and performance. This initial step sets the stage for the exceptional quality and durability of the final products.

Thorough Inspection:

Rigorous inspection protocols are implemented as part of the business process to scrutinize incoming raw materials for compliance with predefined standards. Through meticulous testing and analysis, any deviations from quality parameters are promptly identified and addressed, ensuring consistency and reliability in the manufacturing process.

Precision Machining:

Armed with state-of-the-art machinery and precision tools, skilled machinists embark on the business process of shaping raw brass materials into intricate components. Utilizing advanced CNC machining techniques, each component is meticulously crafted to precise specifications, guaranteeing uniformity and accuracy in every detail.

Exquisite Finishing:

After machining, brass components undergo meticulous finishing processes as part of the business process to enhance their appearance and functionality. From polishing to plating, specialized techniques are employed to achieve the desired surface finish, whether it be a lustrous shine or a protective coating that enhances durability and corrosion resistance.

Final Testing:

Before proceeding to the next stage in the business process, every brass component undergoes comprehensive testing to validate its performance and integrity. From dimensional accuracy to mechanical properties, stringent tests ensure that each component meets the highest quality standards and exceeds customer expectations.

Secure Packing:

With quality assured through the business process, brass components are carefully packed using robust packaging materials to safeguard them during transit. Each component is meticulously arranged and cushioned to prevent damage, ensuring that they arrive at their destination in pristine condition.

Swift Shipments:

Leveraging efficient logistics networks and streamlined processes as part of the business process, swift shipments are arranged to deliver brass components to clients on time Whether across the country or around the globe, reliable shipping partners ensure prompt delivery, minimizing lead times and maximizing customer satisfaction.

Happy Clients:

Ultimately, the success of the business process hinges on the satisfaction of clients. By consistently delivering brass components of exceptional quality, precision, and reliability, manufacturers forge lasting relationships with clients who trust in their expertise and rely on their products to enhance their operations.

In conclusion, the manufacturing business process of brass components is a meticulous journey characterized by attention to detail, precision craftsmanship, and a commitment to excellence. From sourcing quality raw materials to delivering flawless products, each step in the business process is carefully orchestrated to ensure client satisfaction and the success of the manufacturing enterprise. Through unwavering dedication to quality and customer satisfaction, manufacturers of brass components continue to drive innovation and excellence in the industry, setting the standard for precision engineering and reliability.